mbs type rod mill

Rod Mill is also known as wet type rod mill MBS rod mill rod grinding mill or crushing mill Rod mill is widely used grinding machine to grind all kinds of ore and rocks in metal and nonmetal mining sand making industry and so on

WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Rod Mill is also known as wet type rod mill MBS rod mill rod grinding mill or crushing mill Rod mill is widely used grinding machine to grind all kinds of ore and rocks in metal and nonmetal mining sand making industry and so on

Rod grinder can be divided into dry rod mill wet type rod mill and rotary rod mill according to working way and can be divided into limestone rod mill and mineral rod mill according to types of materials

wet type rod mill advantages and disadvantages of ball mill advantage wet ball mill machineAdvantages Of Wet Ball Milling Xinhai rod mills include overflow rod mill end peripheral discharge rod mill and center peripheral Xinhai alloy slurry pump has cantilever type and horizontal type and the main advantage and disadvantages of ball mill advantage Ball Mill is a milling

Fote Machinery is major in producing ball mill rod mill magnetic separator and other ore processing plant with reasonable pricewelcome to visit for purchasing

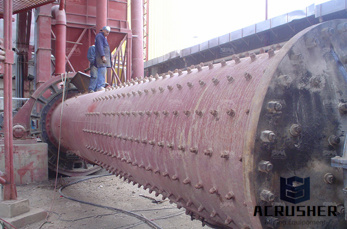

Wet type rod mill is formed with feeding part charging part cylinder discharging part bearing part transmission part electrical appliance part and foundation part Cylinder is made up of steel plates and the cylinder body often uses waveforms stepped or wedge liner

Common examples are rod and ball mills both of which are of the rotary drum type which rely on internal grinding agents to achieve their milling action Unlike the ball mill which utilizes a large number of hardened steel balls to impart the grinding action the rod mill uses steel rods lying within the drum and parallel to its axis

The rod grinding mill has two types one is wet type rod mill and the other is dry rod mill which has been told in the past and the two types grinding mills have the advantages that cannot be caught up with so easily by others such as high efficiency high production

The ball mill is a key piece of equipment for grinding crushed materials and it is widely used in production lines for powders such as cement silicates refractory material fertilizer glass ceramics etc as well as for ore dressing of both ferrous and nonferrous metals The ball mill can grind various ores and other materials either wet or dry

Ball mills designed for long life and minimum maintenance overflow ball mill sizes range from 5 ft x 8 ft with 75 HP to 30'' x 41'' and as much as 30000 HP Larger ball mills are available with dual pinion or ring motor drives Our mills incorporate many of the qualities which have made the Marcy name famous since 1913

F 80 is the mill circuit feed size in micrometers Rod mill A rotating drum causes friction and attrition between steel rods and ore particles citation needed But note that the term rod mill is also used as a synonym for a slitting mill which makes rods of iron or other metal Rod mills are less common than ball mills for grinding minerals

The Center Peripheral Discharge rod mill is also used for wet grinding but produces a coarser product than the overflow type Either the End or Center Peripheral discharge rod mill can be used for wet or dry grinding Whatever the type the rod mill is used to produce a coarse product whereas the ball mill is used to produce a finer product

The Center Peripheral Discharge rod mill is also used for wet grinding but produces a coarser product than the overflow type Either the End or Center Peripheral discharge rod mill can be used for wet or dry grinding Whatever the type the rod mill is used to produce a coarse product whereas the ball mill is used to produce a finer product

The main components of the course Rod wet type is a large tube diameter and length via the actuator so that it slowly turned material feed from the door of the tube the tube due to impact throwing and of stone and iron ore ball mill the material to be crushed to powder

JeanPaul Duroudier in Size Reduction of Divided Solids 2016 374 Performance Rod mills are used in an open circuit between crushing and the ball mill They often operate in wet and where the pulp contains up to 50 solid by mass This machine is equally very applicable to dry where it could take a feed that has achieved 6 moisture

Figure 82 Media motion in the tumbling mill 81 Grinding 811 Grinding action Industrial grinding machines used in the mineral processing industries are mostly of the tumbling mill type These mills exist in a variety of types rod ball pebble autogenous and semiautogenous The grinding action is induced by relative motion between the

The energyefficient wet type rod grinding machine produced by Henan Mining Machinery uses the rolling bearing bush to replace the sliding bearing bush Compared with sliding bearings the wet type rod mill with rolling bearing can save energy 10 to 20 In the case of the same power the production capacity can be increased to 10 to 20

The Rod Mill is the same as the Ball Mill in the construction and available to both of wet and dry processing Unlike the Ball Mill however the Rod Mill uses rods instead of balls as the grinding medium As a result its uses are different from those with the Ball Mill

Features Overflow Type The overflow type of Ball Mill is designed to overflow and discharge materials from the trunnion on the outlet side By combining it with a mechanical classifier or wetprocessing cyclone you are able to extensively use this type for grinding in closed circuit or for special applications such as regrinding in open circuit

Apr 09 2015· The process can be wet or dry but generally it is carried out wet Maximum rod length is about 6 to 7 meters otherwise there is a risk of the rods bowing The drum diameter is limited to 06 or 07 times the length of the mill Rod mills are used for grinding hard minerals

Probst Class Machines for industrial process technology More than any other machinery producer PUC is a name that stands for longevity in connection with emulsifying dispersing and suspending machinery and equipment In industry the PUC name has been synonymous with colloid mills

Rod Mill Rod Type Sand Making Machine Rod Mill Machine manufacturer supplier in China offering Wet Type Rod Mill Rod Type Sand Making Machine 50600tph Limestone Crusher Plant with Competitive Price High Quality Sand Production Line 120150th and so on

Grinding Rod or Ball Mill TYPE D Has single weld triple flanged construction which means the shell is furnished in two sections flanged and bolted in the center All flanges are double welded as well as steel head to shell note design

Uganda Wet Type Rod Mill The energyefficient wet type rod grinding machine produced by Henan Mining Machinery uses the rolling bearing bush to replace the sliding bearing bush Compared with sliding bearings the wet type rod mill with rolling bearing can save energy 10 to 20

Autogenous and SemiAutogenous Mills The optimum solution for wet grinding a rod mill and some or all of the work of a ball mill Because of the range of mill sizes available circuit and accounts for the current popularity of this type of size reduction in modern mineral processing plants

WhatsApp)

WhatsApp)