Raw Mill In Cement PlantCement Making Plant

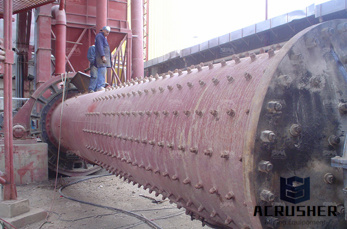

Raw Mill In Cement Plant A raw mill is the equipment used to grind raw materials into rawmix during the manufacture of cement Its mainly used in grinding raw materials and end products in cement plant

WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Raw Mill In Cement Plant A raw mill is the equipment used to grind raw materials into rawmix during the manufacture of cement Its mainly used in grinding raw materials and end products in cement plant

For more Cement Plants visit our This mill is considered to be in excellent condition It has been used for 6 years only in service grinding both Cement Raw Materials and Granulated Blast Furnace Slag To see more VRMs check our

Cement grinding Vertical roller mills versus ball today is the most used mill for cement grinding Over the last three decades the vertical roller mill has bee the preferred mill for grinding of raw materials The grinding efficiency of the vertical roller mill bined with an ability to dry grind and classify within a single unit gives the vertical roller mill

Metallurgical ContentRAW CEMENT GRINDINGWET VS DRY Grinding of CementCLINKER GRINDINGCement Grinding MillsHigh Efficiency Cement Grinding Mill The principle of Grate Discharge grinding is nearly universally adapted in the cement grinding industry Grate Discharge Ball Mills are the rule rather than the exception Rod Mills for raw and finish grinding begin to enter the picture Larger and larger diameter mills become common Lengths tend to shorten Cement grinding

The GRMK vertical cement mill of CHAENG adopts a new generation of cement grinding technology which integrates grinding drying and powder selecting functions It can save 30 of power per ton compared with traditional ball mill

Thanks to its expertise in comminution processes Fives provides taylormade grinding plants To offer the most adapted answer to Clients project requirements Fives relies on a range of efficient proprietary technologies such as the FCB Horomill the FCB Bmill the FCB Emill

Our vertical grinding mill applies for limestone clinker clay gypsum etc Cement vertical mill is also called a vertical milling machine AGICO customizes any sizes of

Ball mill is the cement crushing equipment in the cement plant Compared with open circuit ball mill the closedcircuit ball mill has high efficiency high output low cement temperature and good comprehensive benefit It is the best choice for a cement plant

Grinding systems in cement production make up approximately 85 to 90 percent of total plant electrical energy consumption As vertical roller mills are 30 to 50 percent more efficient than other grinding solutions they give cement plant owners a great opportunity to

We are the bigest exporter of Cement Plant Equipment like Air Blower Conveyors Bucket Belts and Chain Elevators Cement Plant Crushers Grinding Mills Feeders storage silo packaging machines etc We are known for our Energy Efficient and Environmentfriendly Cement Plant Technologies

Coal Mills for Cement Plants Coal grinding mills LOESCHE coal grinding mills are distinguished by characteristics that improve efficiency safety and environmental protection from the standard version to topoftherange installations

Chanderpur Group Works Pvt Ltd Leading of Cement Plant Manufacturers EPC Cement Plant Suppliers Cement Plant Technology Ball Mill Manufacturers Cement Plant Upgradation Grinding Mill Manufacturers CPG holds deep domain knowledge of the industry and hence is equipped to offer customized service that are directed to meet the needs of clients from cement plants

Grinding Mills Call Columbia Steel for our full line of cement plant parts for rod ball and semiautogenous grinding mills Preheater Kiln Parts Reduce your cost per ton with our thimbles inlet trays nose ring segments tail ring segments and inlet castings

CEMTEC provides grinding solutions with rod mills for wet and dry grinding applications These mills are available with either a slide slide shoe or spherical rol ler bea ri ng as well as with either gear rimpinion direct or central drive they can have a rubber or steel lining

Mills for grinding cement coal or minerals Christian Pfeiffer designs and builds grinding plants for many different feed materials and finished products Our mills are as varied as the requirements of our customers Ball mills vertical mills compact mills jet mills or roller mills

This paper mainly introduces the raw mill in cement plant In order to achieve the desired setting qualities in the finished product a quantity 28 but typically 5 of calcium sulfate usually gypsum or anhydrite is added to the clinker and the mixture is finely ground to form the finished cement powder This is achieved in a cement raw mill

Columbia Steel offers a full line of wear parts for rod mills ball mills and semiautogenous grinding SAG mills for cement plants Made in USA

Aug 30 2012· Material is directly conveyed to the silos silos are the large storage tanks of cement from the grinding mills Further it is packed to about 2040 kg bags Only a small percent of cement is packed in the bags only for those customers whom need is very small

WhatsApp)

WhatsApp)